Y-man has a “FINALLY!” moment with his new slugs and new stock…

Hello y’all… Y-man here again…

I have FINALLY achieved what I have sought for more than five years now: self-cast and reloaded slugs, achieving accuracy, consistent performance and reliability. I also have fabricated a much better shotgun stock now (see photo above)

I finally got myself a Lyman Sabot Slug mold from the US in February 2013, and a BPI Roll-crimper. This has helped me arrive at where I proudly am today.

I cast and loaded some Lyman 525gr Sabot Slugs, in different configurations, with varying wad and buffer material considerations.

Everything was properly measured, and weighed – basically, what I was doing was casting the Lyman slugs, at about 525 grains, (Or 34 grams) taking a regular birdshot shell, cutting open the shell, pouring out the shot and loading the cast slug into the wad in the shell, then re-crimping using my BPI roll-crimper.

The major differences with normal reloading (Or what I like to call the “Y-man way…”) were the following innovations.

1. I used hard plastic donut buffer disks under each slug. In some, I used softer plastic disks, while in some, the material was more rigid.

2. I also inserted a small plastic ball into the cavity of each slug: just like the Federal Tru-Ball slug design.

The ball is to center the slug in the bore, and to prevent the wad being scrunched into the cavity. This is also to ensure clean separation of slug from wad.

2. I also inserted a small plastic ball into the cavity of each slug: just like the Federal Tru-Ball slug design.

The ball is to center the slug in the bore, and to prevent the wad being scrunched into the cavity. This is also to ensure clean separation of slug from wad.

Being able to properly roll-crimp is also a wonderful development.

VIDEO

I built up a large number of shells for testing, and of course, I decided to test-fire these new, promising slugs, and use the opportunity to also test my new improvised stock. (After the last model almost tore my cheek open with vicious cheek-slaps, I had to re-work my stock.) when I went up north to visit family at the end of August 2013.

I fired a total of 14 slugs, firing them with my Mossberg 500A Smoothbore Shotgun with my left elbow braced against a truck hood (Or “Bonnet” as we call it here…), and firing from exactly 35 meters (Or 115 feet, or 38.2 yards.) (This was accurately measured, not stepped or estimated.)

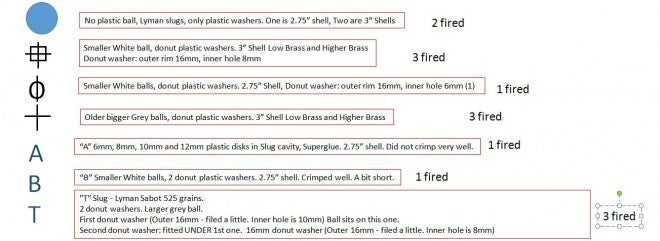

I made sure that the different configurations of slugs were properly planned, so there would be no mix-ups, and the results would be very clear. I actually drew up a shooting schedule to ensure my slugs were well arranged. Each slug was clearly marked with symbols to differentiate from others…

Slug/ Shooting plan September “Expedition”…

With each shot, and each subsequent batch of slugs, my excitement grew: I was getting accuracy! Consistent accuracy! At 35 meters!

I used an innovative target system: an eighteen-inch wide by four-foot tall HARD wood plank (Two inches thick) on which I hung my bullseye targets – the metal cover plates of discarded computer hard drives (Dimensions- six inches tall by four inches wide.)

In the first batch fired, out of five shots, I achieved a 6-inch circle of hits, including one miss. Two were on the target plate.

The second batch of four shots opened up a bit more to 8 inches, but ALL on the plank.

The second batch of four shots opened up a bit more to 8 inches, but ALL on the plank.

And the third batch of five rounds had a spectacular double-hit-in-one-hole… (Two slugs went through the same hole…Both on the metal plate) Yes, there were a few misses, but all within an eight-inch circle, and within 4 inches of point of aim for the last miss.

See video of the testing experience here. (Please drop a comment or two…)

By the third batch of slugs, I had quite a cheering audience of nearby villagers, and after this, I had to stop, as with each shot, costing equivalent of $3 here, my conscience bothered me as I felt it seemed I was “wasting” away the equivalent of a family meal for each poor villager. I kept the rest of the slugs for my self-defense hoard of ammo.

After shooting, I gave the village chief the fired empties: in the villages, they usually do some reloading, using locally made gunpowder, and stuffing the shell with locally made shot – lead melted from old car batteries, and dripped from height into buckets of rain water.

I searched for, and recovered the fired wads, and out of fourteen fired, I recovered thirteen wads, several buffer disks, and two slugs. Three wads were badly shredded, eight were not too bad: they lost their petals, and two were very good.

I also enjoyed using my new stock design. For the very first shot, I leaned forward a bit too much, and had my lip against the metal bracket of the stock. Needless to say, I did not do this for the subsequent thirteen shots! I only had a small split lip from the first one…

It was quite an exciting experience, and shows the possibilities that have opened up for me…

I know what direction to go now, with my designs and projects. In a way, it is almost an anti-climax: the feeling is more like, “Okay, this is done now, so what next?”

Meanwhile, a certain ”someone I barely know” seems to be building up quite an arsenal! Check out his line up below

1. Mossberg 500A 12ga with improvised stock and self-reloaded Lyman slugs…

2. Turkish Semi-Auto 12ga Shotgun (“Magnum”)

3. Crossman Air Pistol (With modified sights, as well as regular and “Penetrator” pellets…)

4. Daisy Sling Shot (With Steel Ball bearings…)

5. Gerber (Bear Grylls) Survival Knife (With built in Firestarter)

6. Cold Steel Kobun Knife…

7. Self-Fabricated “tactical” dagger.

8. SOG Tomahawk

9. Tactical shovel with serrated edge (Modified)

2. Turkish Semi-Auto 12ga Shotgun (“Magnum”)

3. Crossman Air Pistol (With modified sights, as well as regular and “Penetrator” pellets…)

4. Daisy Sling Shot (With Steel Ball bearings…)

5. Gerber (Bear Grylls) Survival Knife (With built in Firestarter)

6. Cold Steel Kobun Knife…

7. Self-Fabricated “tactical” dagger.

8. SOG Tomahawk

9. Tactical shovel with serrated edge (Modified)