Do It (Kind Of) Yourself: HK G36 Rifle

H&K has never made a true G36 rifle available to civilians in the USA mostly due to import regulations and what I assume would be a lack of demand (lets face it, your average consumer is happy with one of the many AR variants that have taken over the semi-automatic 5.56 rifle market). However in the 90′s to comply with the 1989 import ban on foreign “assault weapons” and the now expired 1994 Federal Assault Weapons Ban, H&K came up with an idea to market a new sporting rifle known as the SL8 that was a cousin of the G36. The rifle functioned via the same operating system but looked a whole lot less scary and a whole lot more like an old IBM computer keyboard:

VIDEO - HK G36 Rifle

While H&K did finally offer the gun in black, the fact remained that even though the 1994 Assault Weapons Ban expired, the ’89 ban persists to this day. The now discontinued SL8 was never a big seller due in part to its high price tag and the fact that it is a neutered version of a neat rifle, but the HK community (an especially crafty bunch) found a way to turn this horse designed by committee into what they wanted: a G36 rifle.

Now I bought an SL8 on September 17th, 2011 for the price of $1600 new in the box from my favorite local gun shop. I knew immediately that the rifle would be converted, so I never even shot the gun in stock SL8 form. Here she is the day I got her laid out across my garage floor:

The conversion is among the most complex gunsmithing projects I had ever undertaken, as it requires a significant amount of plastic welding (a skill I lack both the know-how and tools to perform) and so the hardest part is converting to take double stack magazines and welding on a g36 rear receiver stub. The SL8 has a section of the receiver indented so as to prevent the insertion of the double stacks. Also, the sl8 bolt head has a slanted lug so that it will not feed from double stacks, so you need a g36 bolt.

To start the process I ordered:

G36 Bolt Head- US HDPS Manufacture

G36 30 Round Mags

HK G36 High Capacity Mag Well- Black

Stock Block For HK SL8 Conversions (to shoot it before I did the rear of the receiver)

G36 Rear Stock Axle Pin For SL8 To G36 Stock Conversion

G36 FBI (0,1,) Lower HK German New

G36 Recoil assembly

G36 & HK SL8 Sight Rail With Front & Rear Sights

HK G36, G36K Full Size Folding Stock

G36 Bolt Head- US HDPS Manufacture

G36 30 Round Mags

HK G36 High Capacity Mag Well- Black

Stock Block For HK SL8 Conversions (to shoot it before I did the rear of the receiver)

G36 Rear Stock Axle Pin For SL8 To G36 Stock Conversion

G36 FBI (0,1,) Lower HK German New

G36 Recoil assembly

G36 & HK SL8 Sight Rail With Front & Rear Sights

HK G36, G36K Full Size Folding Stock

These parts ran me $1,284.59.

Also, I will need a number of 922r compliance parts, which will include-

US made Sear

US made Trigger

US made Floor plates for magazines

US made Piston

US made Op Rod

US made Bolt Head

US made Flash Hider

US made Sear

US made Trigger

US made Floor plates for magazines

US made Piston

US made Op Rod

US made Bolt Head

US made Flash Hider

Yes, 922r sucks and this bundle of parts cost me $424.64.

But wait, there is more you have to spend if you want that authentic look!

I just had to have the Hensoldt dual optic!

Which after shipping ran me another $709.99.

Once you have your gun and the parts you can start converting to the best of your ability. The first step is to swap your SL8 trigger group over to your G36 lower using your 922r parts. You can do this at home with your hands and a drill press (you need to drill a hole to accommodate the SL8 FCG).

This took me and my friend CJ about 2 hours in my garage, as the SL8′s FCG has parts that neither of us had ever seen before. You can see a breakdown of the trigger group here:

http://alpinetek.netfirms.com/guns/SL8/breakdown/

Basically strip your SL8 lower of its FCG, drill a hole on your new lower, and swap the parts over. This sounds simple, but I swear that a lot of profanity was involved and 3 or four hands were needed constantly. Not to mention those lovely 922r parts got to be put in.

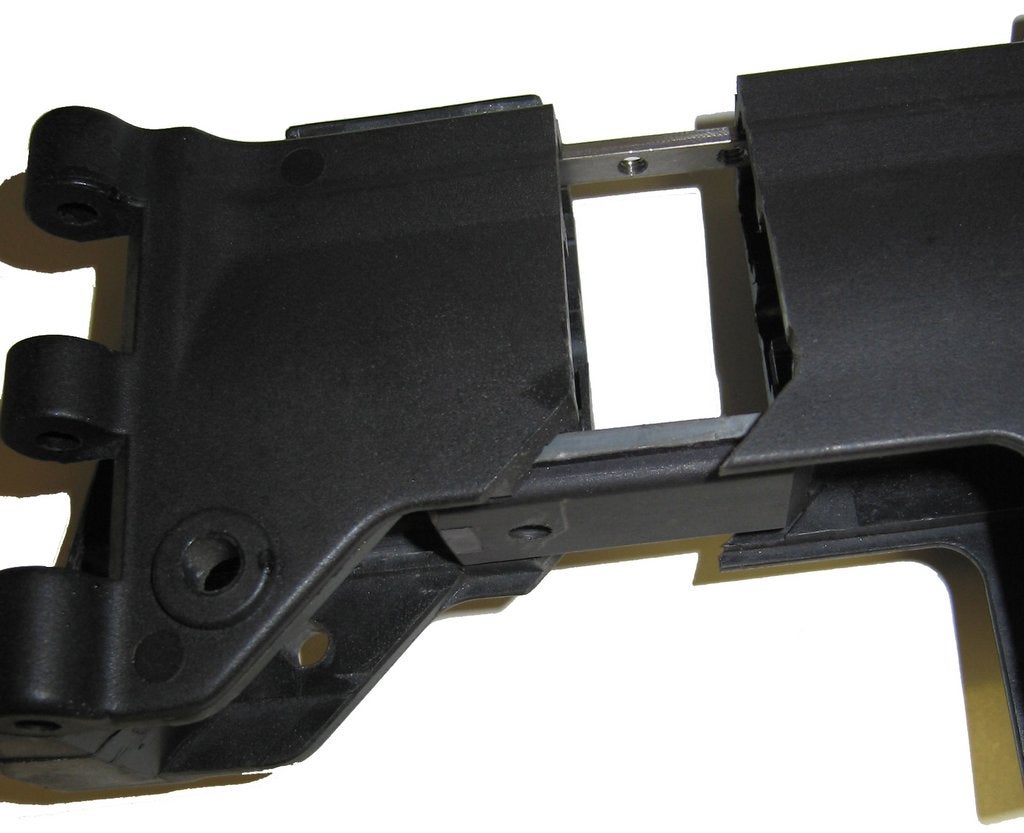

That day I also milled out the magazine well to accept double-stack magazines. This is not my photo, but it is more of less how you do it:

I then put the HDPS stock block to use by aligning a g36 stock and punching in an axle pin, and I threw it together for a quick look see. At this point here is how she looked:

This was about as far as I could take it myself, so I had to outsource the next few steps to a professional.TPM Outfitters located in Carrolton, Texas are a business by me that specialize in H&K products. I did not know that they existed before I had started on this project, but I conscripted them to turn my barrel down, thread it, and get the plastic welding done (something they outsourced to a gentleman they know).

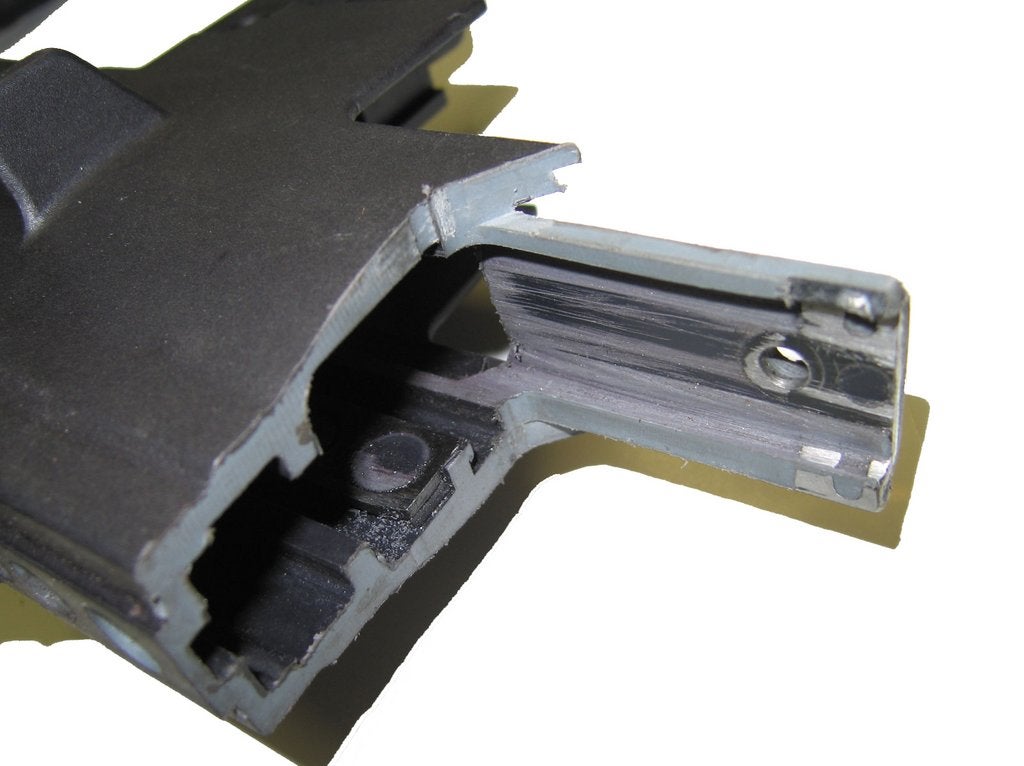

The following is a series of photographs depicting how the plastic welding is done on these guns. First, the magwell cut is reinforced by the placement of a metal bar:

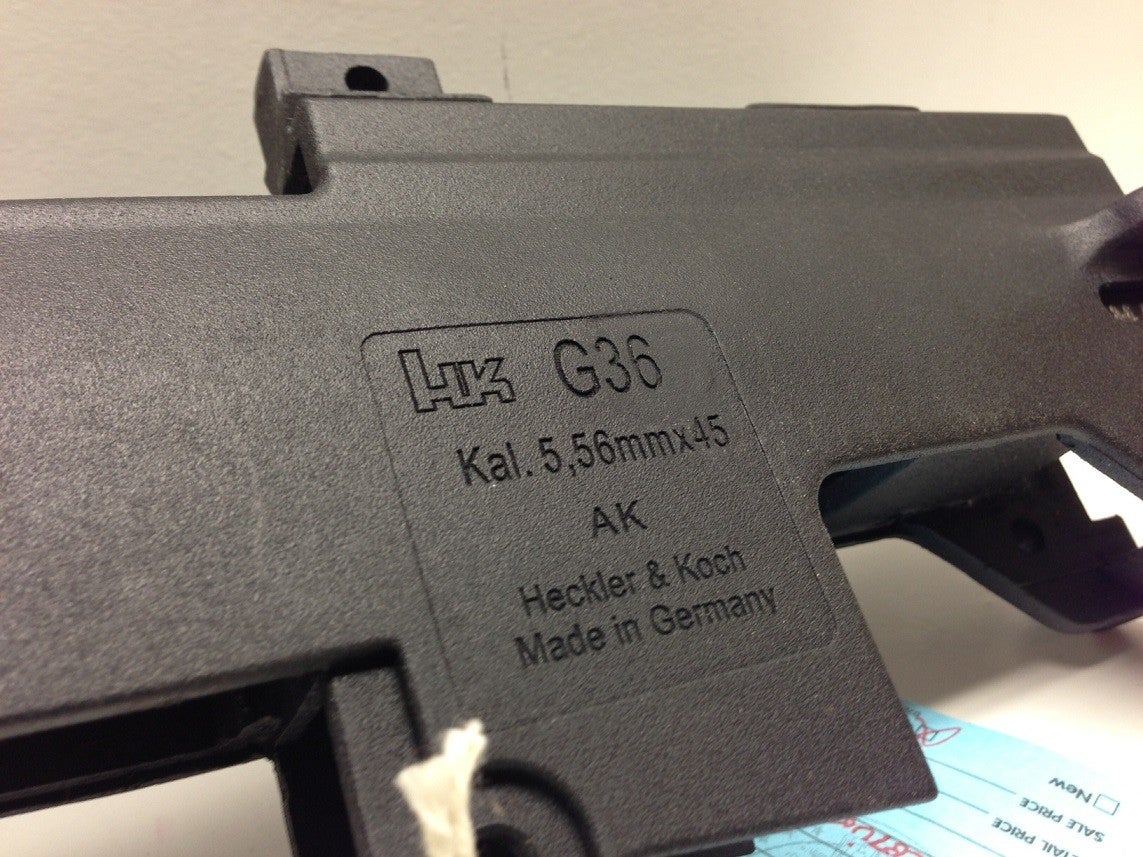

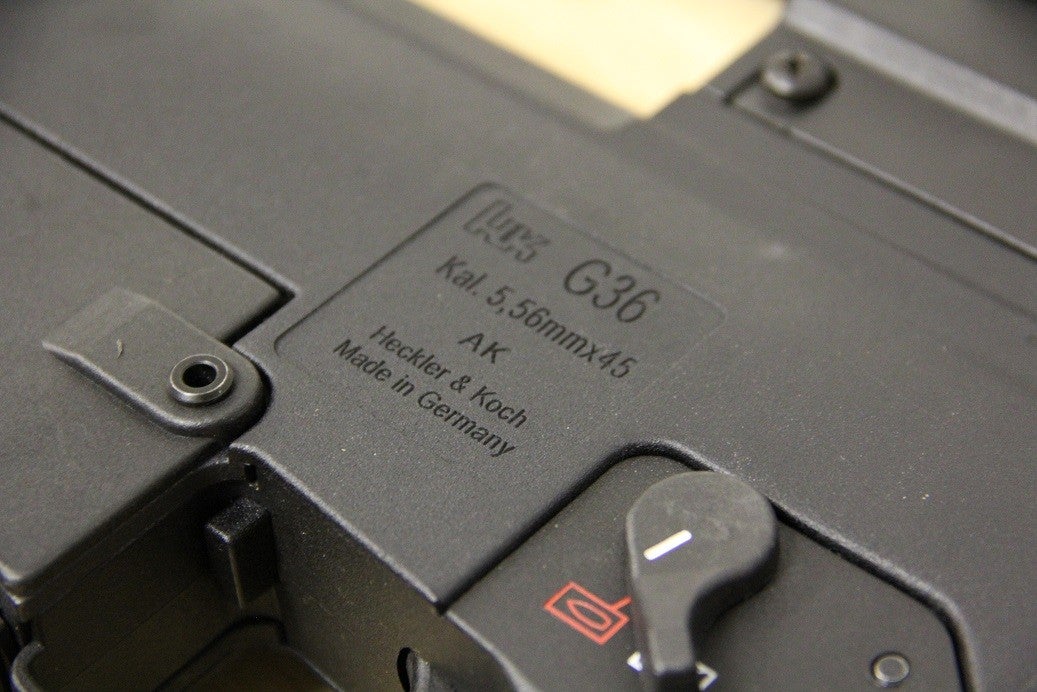

The bar is then covered and laser engraved with authentic g36 markings:

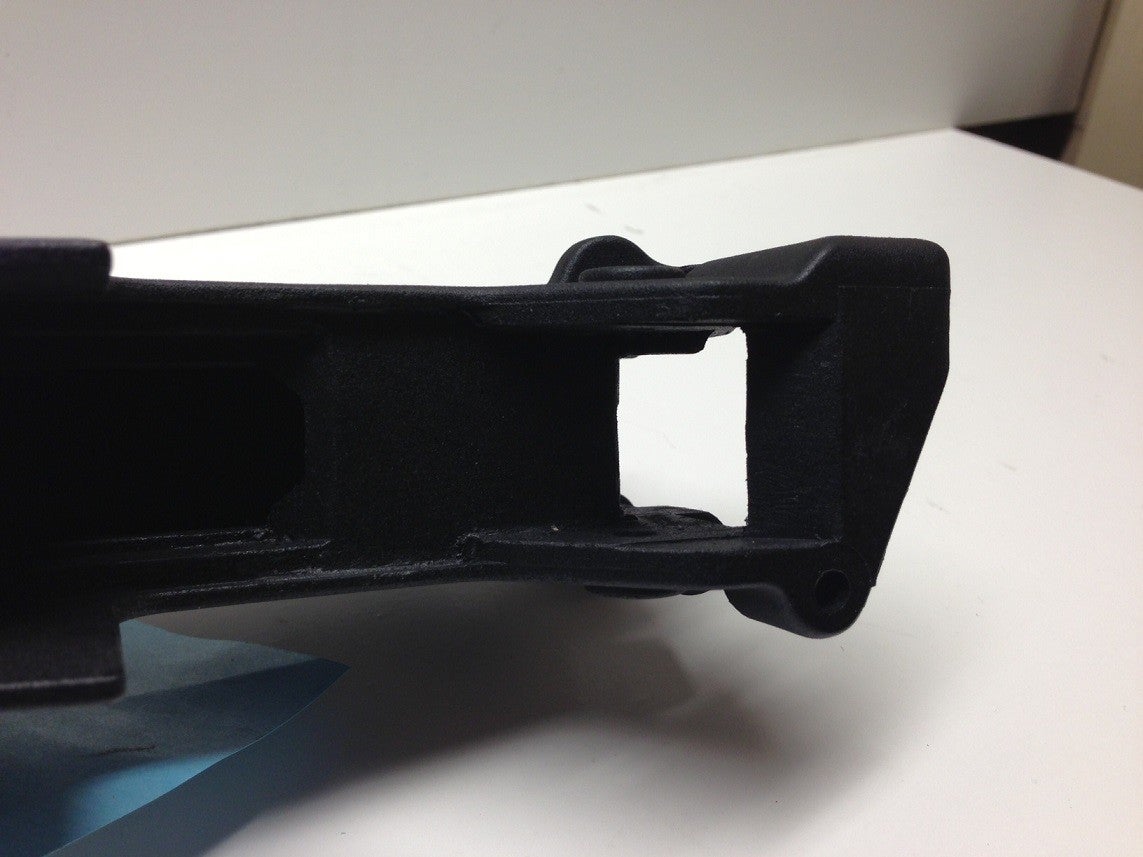

Now here is the scary part. The rear of the SL8 must be cut off and a g36 receiver stub must be put in its place:

The stub and the SL8 receiver are not simply plastic welded together either; a steel bar is put in-between the two for strength:

The two sections are then brought together and then welded:

After proper welding you are left with this:

And of course the markings that formerly said “SL8″ are refinished with g36 markings:

The next step is to mill this nub on your SL8 carrier off so that it will clear the new g36 receiver stub:

Alas after two years of working on this project on and off, I finally got to pick up the gun and assemble it. As I held the product in my hands for the first time It seemed like I had a whole new rifle. I ditched the stock block and the original sight rail I bought and bam, suddenly I felt like I had a real G36 rifle in my hands:

Also for giggles, I just had to get a suppressor adapter and throw my Gemtech G5 on it!

And there she is; A project two years in the making is finally completed and is perhaps the most unique gun in my collection. I have put maybe 500 rounds of both m193 ball and M855 ammunition through it without a stoppage and it turns some heads at every range it goes to. Most people ask “what is that thing?” while others ask “how the hell did you get that?”. I have yet to have anyone know it started life as an SL8 approach me and ask about the conversion.

So there you have it, a civilian G36 in the USA. It isn’t impossible, but it isn’t easy either. Now if this is something you have considered, let me tell you the good, the bad, and the ugly.

The Good:

- Shoots great! Very reliable and the trigger is very good

- The dual optic is very neat and has a built in range finder and a nice reticle

- Very low recoil impulse

- Fully ambidextrous

- Light for its size and barrel length

- Feels very solid for a plastic gun

- Turns heads and generates traffic

- Fine asset to any collection

The Bad:

- The eye relief and FOV on the dual optic are terrible!

- The battery for the red dot is proprietary

- The unique recoil impulse has two stages akin to a SCAR (odd to describe but very weird)

- Magazines are proprietary and can be expensive (albeit Magpul now makes g36 mags)

- It isn’t and will never be a real G36 rifle

The Ugly:

- The price tag. I have about $4500 into this gun

- Time to completion; This project has taken me two years to complete due to turnaround times and parts acquisition

So that is that. If you have any more questions please feel free to ask me and I will answer them to them to the best of my ability in the comments!