Do You Know Your HK’s Parents?

During this holiday season, perhaps you would like to take a break from visiting with your spouse’s parents – so how about getting to know your rifle’s parents?

video

For a long time, the whole line of long guns made by H&K was all based around a single concept: roller-delayed blowback (sometimes erroneously called roller locked). The H&K 91 battle rifle used it, as did the 93, 94, 21, 33, 41, PSG-1, and MP-5 (and all the variants of them). Pretty impressive, really, that they were able to create such a wide array of guns from SMG to sniper rifle all based on the same basic principle.

So how does it work? The bolt in any of these weapons has a pair of rollers on the left and right sides, which push out into semicircular recesses in the barrel extension when in battery and ready to fire. This is a very effective way to build an gun, because it is cheap and simple to make precise rollers, and the semicircular recesses to match them are also easy to make. You need only push a solid block between the rollers to prevent them from retreating back into the bolt, and your gun is securely locked. The German MG-42 of WWII fame used this system to great effect, and it is on the shoulders of this giant that our H&K genealogy begins.

In June 1943 the R&D division of Mauser, under the direction of a man named Ott von Lossnitzer, decided to pursue the goal of using a roller-locking system like the MG42 in a Gewehr 43 rifle. The G43 used an expensive and somewhat fragile Kjellman-style flap locking system, and Mauser was looking for a way to build a similar rifle less expensively. By December of 1943 they had completed a test model of the converted G43 (which was designated the Gerät 03), and were putting it through a 5000-round endurance trial. It’s important to note that this rifle was a fully locked design, using a gas piston to unlock, while the H&K we all know today is a delayed blowback, with no gas system.

Now we come to the critical development. One of the engineers working on the Gerät 03 – a man by the name of Dr. Karl Maier – noticed something unusual during firing. When the bolt on the Gerät 03 slammed forward into the barrel extension upon loading a new round, it would bounce slightly open again before settling down into the intended locked position. It was possible for the gun to be fired in the middle of this bounce, and when this happened the bolt would open much faster than the rifle’s gas piston was supposed to make it.

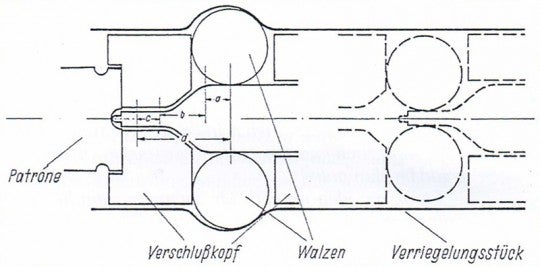

Gerät 03 diagram from Karl Maier’s notes. Note that the rollers rest on parallel surfaces, so no amount of force pushing back on the bolt can cause it to unlock.

The block used to push out the rollers had the firing pin at its tip, and an angled wedge to smoothly move the rollers. What Maier realized was happening during these out-of-spec firings was that the rollers were resting on the angled sides of the wedge when discharged, instead of on the main parallel sides of the block. As a result, the force pushing back on the bolt would slide the rollers in by itself, without and input from the piston needed. This sequence of events kept rolling around in Maier’s head while he worked, and by the middle of January 1944 he had conceptualized a brand new action, which would be simple and cheaper still than the roller lock.

Diagram of StG-45(M) locking system from von Lossitzer’s notebook. Note here that the rollers rest on angled surfaces, so pushing on the bolt will cause it to unlock.

Maier’s idea was to carefully calculate the angle of the wedge in the system, and get rid of the gas piston. By using the basic principle of a wedge, he would take the recoil force pushing back on the bolt during firing and split it into two components. Some of the force would push out into the receiver and center wedge, and some would continue to push backwards. By using the right angle, he could reduce the rearward force to just the right amount of force to open the bolt only after the bullet had left the muzzle and pressure in the barrel had dropped to a safe level. This is the principle used in simple blowback submachine guns and pistols, but in those guns the timing is controlled by changing the weight of the bolt. Maier’s idea was to redirect the force pushing on the bolt, and thus achieve the same result without adding a lot of weight.

video

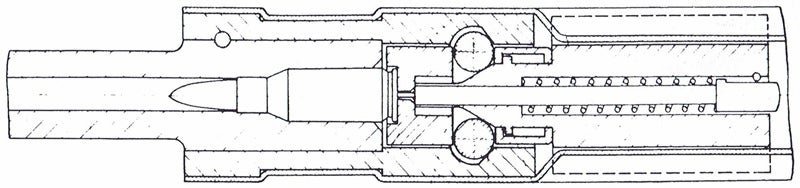

Mauser subsequently build a rifle in 8mm Kurz (7.92x33mm) using this roller-delayed blowback system – the first of its kind. The rifle was called the Gerät 06H, and it was presented in December 1944 to the German military for evaluation. It was very well received, being significantly cheaper and faster to manufacture than the StG-44 rifle, and just as reliable and effective in use. The design was given the designation StG-45(M) (M for Mauser, as other companies were also competing to design the StG-44′s replacement) and an order of 30 guns was placed for further trials.

The parts for those 30 rifles were manufactured, but before they could be assembled into complete guns the Mauser factory was evacuated. Allied forces were on the verge of overrunning the town of Oberndorf, and the Nazis didn’t want the experimental new arms under development there (including the StG-45(M)) to be captured. Of course, the was would be over within weeks and everybody knew it, so the evacuation didn’t really accomplish anything.

In the aftermath of the war, there was a great flowering of interest in intermediate cartridges like the 8mm Kurz as well as the “assault rifle” concept among the Allied powers. The Mauser facilities at Oberndorf were in the French occupation zone, and many former Mauser engineers were put to work by the French developing small arms for an experimental new 7.65x35mm short cartridge. The first result of this work was a carbine designed by Ludwig Vorgrimler which was functionally identical to the StG-45(M). Called the CEAM (Centre d’Etudes et d’Armement de Mulhouse, a research division of the French Châtellerault arsenal) Model I/1, the first prototype was test fired in July 1948. A second design from another former Mauser engineer (Theodor Löffler) was ready in September 1948, and was also effectively a copy of the StG-45(M).

Vorgrimler Model 1 rifle designed for CEAM (photo from “Full Circle” by R. Blake Stevens)

Of the two designs, Löffler’s was preferred. While Vorgrimler continued to work on the program, Löffler’s design was revised several times into what was eventually designated the Model 50/1. This rifle retained the roller-delayed blowback system from the StG-45(M), but was chambered for the US .30 Carbine cartridge. It also included several more design elements which we will recognize on the HK-91, including an integral folding bipod, a rear sight located at the back end of the receiver (instead of over the chamber as with the StG), and a charging handle located forward and above the barrel.

CEAM Model 50/B serial number 6 (photo from “Full Circle” by R. Blake Stevens)

We are getting closer to the H&K 91, but we aren’t quite there yet. In September 1950, Vorgrimler left CEAM and French employment, because of the general preference for Löffler’s rifle over his own, and because he simply wasn’t happy in France. He moved to Spain, where he was to be employed by the Centro de Estudios Technicales de Materials Especiales (Center for Technical Studies of Special Materials) or CETME – a name which should be familiar to HK91 owners.

Ludwig Vorgrimler, circa 1950 (photo from “Full Circle” by R. Blake Stevens)

The Spanish government was also looking for a new rifle, but they wanted a larger full-power cartridge. When Vorgrimler arrived the project had already been underway for 9 months, and the rifle being built was a flap-locked design like the wartime G43. Fighting a lot of skepticism, Vorgrimler managed to get permission to design his own rifle – a roller-delayed gun based on the StG-45(M) and CEAM 50/1 – in parallel. The first prototype (called the CETME Modelo 2) was ready for firing in June 1951, and it made a big impression on the Spanish military. The first CETME rifle was dropped in favor of Vorgrimler’s system, and it was put into production. It is worth noting here that this early CETME rifle was chambered for an interesting 7.92x41mm (yep, 8mm by 41, not 51) cartridge with a very long 100-grain bullet. This interesting ballistic choice allowed the rifle to have a maximum effective range of 1000m while still having a relatively light recoil. Despite having some very interesting potential, this cartridge would be left behind in the wake of NATO standardization on 7.62x51mm.

CETME Modelo 2, designed by Ludwig Vorgrimler using the original StG-45(M) mechanism. Note the curved magazine for the early 7.92x41mm cartridge

Now, we have one last link in the chain – from CETME to H&K. How did that happen? Well, the German armed forces (what little they were allowed to have at that time) expressed an interest in the CETME rifle, and so the Spanish sent over a delegation to discuss production in Germany. Naturally, they went to the Mauser company – the birthplace of the design and a world-renowned arms company. Mauser management, in a stupendous failure of judgement, laughed the Spanish delegation out of the office.

Left unexpectedly out in the cold, the CETME team called up another manufacturing company located in Oberndorf, which happened to be a fledgling startup called Heckler & Koch. It had been founded in 1948 in by two ex-Mauser employees, and for several years was based in Heckler’s own home. By 1954 when the CETME connection was made, H&K was making sewing machine parts, machine tool parts, and dies and fixtures for other companies. The relationship with CETME would become its great opportunity, and allow it to grow into the armaments giant it is today.